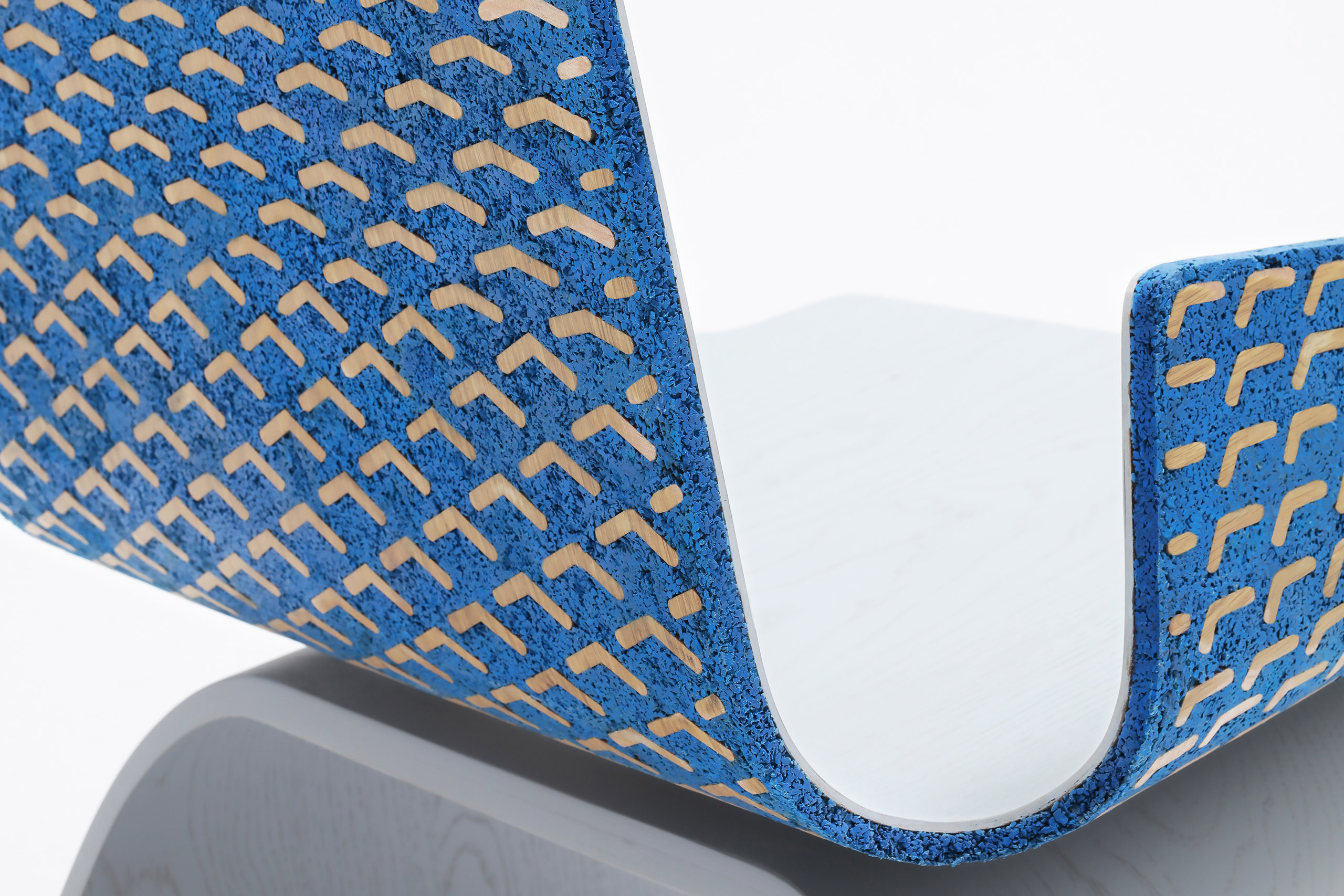

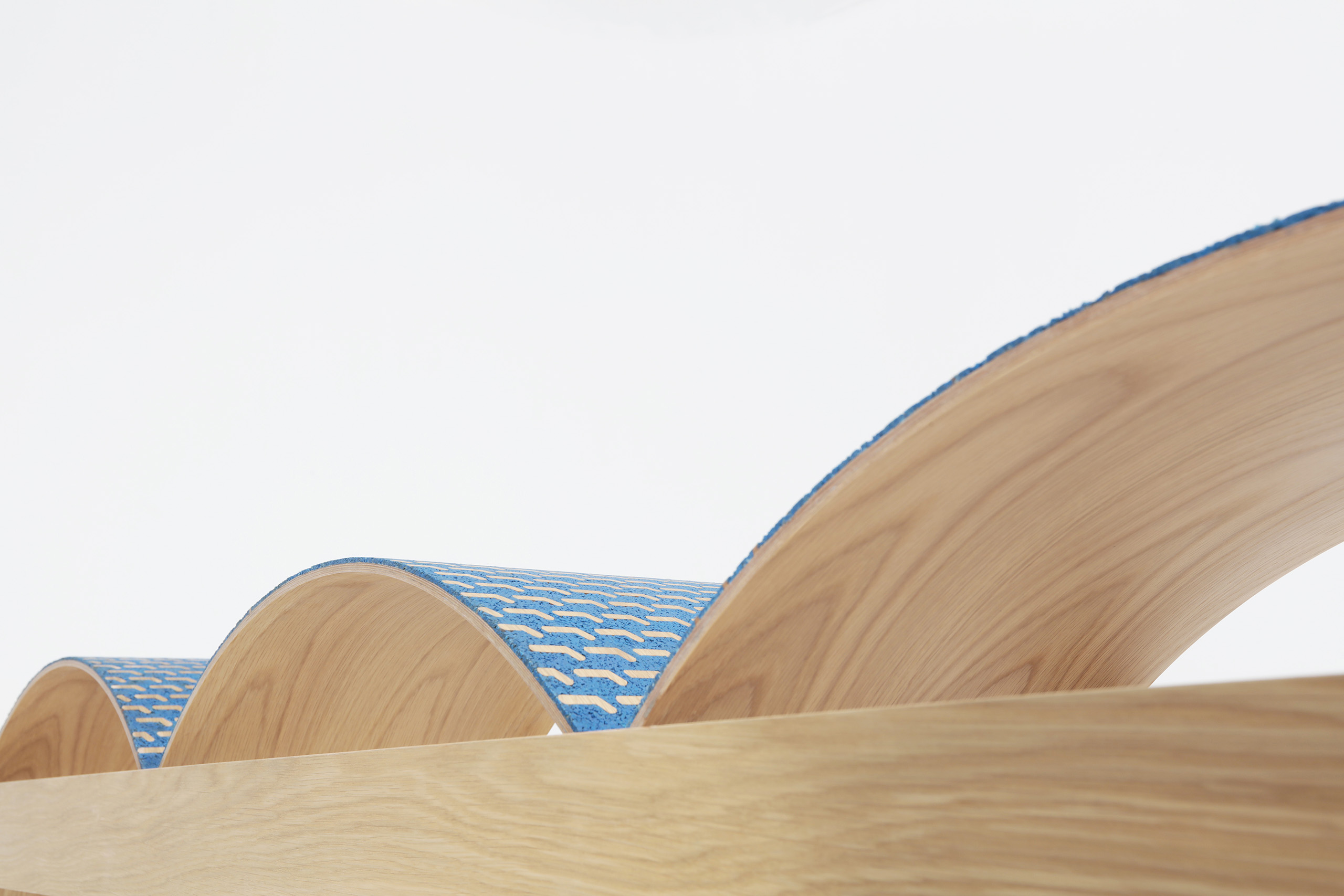

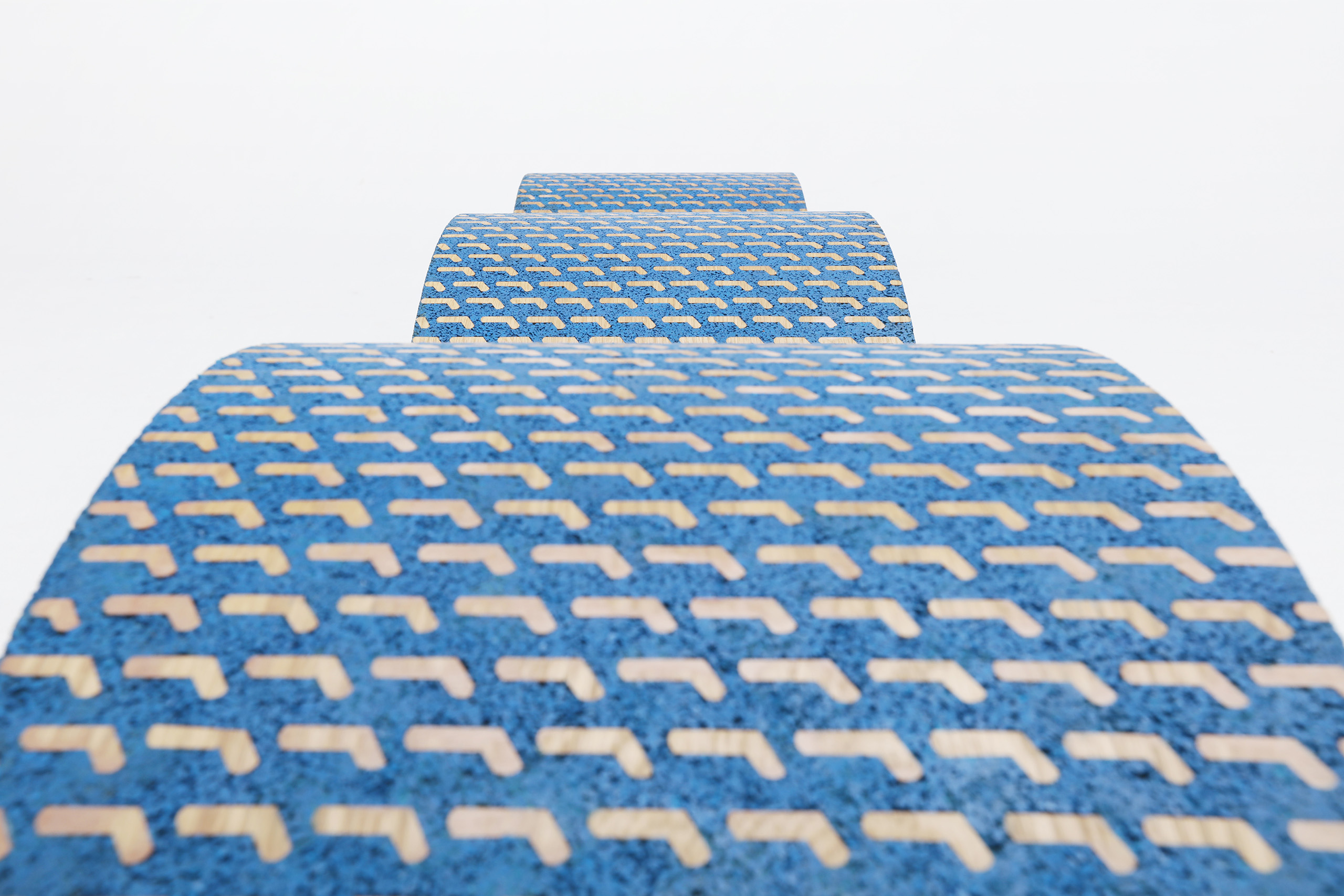

The Flex project is product applications with material innovation combining flexible rubber with rigid plywood. The plywood is milled through CNC machining and filled with rubber to create resilient plywood. The rubber is squeezed as the 'rubber plywood' is deformed under pressure, the rebound tension will get stronger as the pressure increases, so that the two forces give the material a better strength. Different milling structures allow differences in resilience at different areas on the same plywood.

Flex项目是关于弹性橡胶与刚性多层板相结合的材料创新及产品应用。通过CNC加工,将多层板铣削后,把橡胶回填至槽中,创造出具有弹性的多层板。“橡胶多层板”受压力变形时,橡胶将被挤压,回弹的张力会随着压力的增大而变强,两股平衡的力量使材料具备更好的强度。根据不同铣削结构的设计,可以实现不同的弹性大小,也能在同一张板上创造出不同区域的弹性差异。

The Flex project is product applications with material innovation combining flexible rubber with rigid plywood. The plywood is milled through CNC machining and filled with rubber to create resilient plywood. The rubber is squeezed as the 'rubber plywood' is deformed under pressure, the rebound tension will get stronger as the pressure increases, so that the two forces give the material a better strength. Different milling structures allow differences in resilience at different areas on the same plywood.

Flex项目是关于弹性橡胶与刚性多层板相结合的材料创新及产品应用。通过CNC加工,将多层板铣削后,把橡胶回填至槽中,创造出具有弹性的多层板。“橡胶多层板”受压力变形时,橡胶将被挤压,回弹的张力会随着压力的增大而变强,两股平衡的力量使材料具备更好的强度。根据不同铣削结构的设计,可以实现不同的弹性大小,也能在同一张板上创造出不同区域的弹性差异。

The Flex project is product applications with material innovation combining flexible rubber with rigid plywood. The plywood is milled through CNC machining and filled with rubber to create resilient plywood. The rubber is squeezed as the 'rubber plywood' is deformed under pressure, the rebound tension will get stronger as the pressure increases, so that the two forces give the material a better strength. Different milling structures allow differences in resilience at different areas on the same plywood.

Flex项目是关于弹性橡胶与刚性多层板相结合的材料创新及产品应用。通过CNC加工,将多层板铣削后,把橡胶回填至槽中,创造出具有弹性的多层板。“橡胶多层板”受压力变形时,橡胶将被挤压,回弹的张力会随着压力的增大而变强,两股平衡的力量使材料具备更好的强度。根据不同铣削结构的设计,可以实现不同的弹性大小,也能在同一张板上创造出不同区域的弹性差异。

The Flex project is product applications with material innovation combining flexible rubber with rigid plywood. The plywood is milled through CNC machining and filled with rubber to create resilient plywood. The rubber is squeezed as the 'rubber plywood' is deformed under pressure, the rebound tension will get stronger as the pressure increases, so that the two forces give the material a better strength. Different milling structures allow differences in resilience at different areas on the same plywood.

Flex项目是关于弹性橡胶与刚性多层板相结合的材料创新及产品应用。通过CNC加工,将多层板铣削后,把橡胶回填至槽中,创造出具有弹性的多层板。“橡胶多层板”受压力变形时,橡胶将被挤压,回弹的张力会随着压力的增大而变强,两股平衡的力量使材料具备更好的强度。根据不同铣削结构的设计,可以实现不同的弹性大小,也能在同一张板上创造出不同区域的弹性差异。

The Flex project is product applications with material innovation combining flexible rubber with rigid plywood. The plywood is milled through CNC machining and filled with rubber to create resilient plywood. The rubber is squeezed as the 'rubber plywood' is deformed under pressure, the rebound tension will get stronger as the pressure increases, so that the two forces give the material a better strength. Different milling structures allow differences in resilience at different areas on the same plywood.

Flex项目是关于弹性橡胶与刚性多层板相结合的材料创新及产品应用。通过CNC加工,将多层板铣削后,把橡胶回填至槽中,创造出具有弹性的多层板。“橡胶多层板”受压力变形时,橡胶将被挤压,回弹的张力会随着压力的增大而变强,两股平衡的力量使材料具备更好的强度。根据不同铣削结构的设计,可以实现不同的弹性大小,也能在同一张板上创造出不同区域的弹性差异。

FLEX

Material Research

Furniture Design

Manufacture: A-Zenith

Dezeen Awards 2022

Gold Idea Design Award 2019

FLEX

Material Research

Furniture Design

Manufacture: A-Zenith

Dezeen Awards 2022

Gold Idea Design Award 2019

FLEX

Material Research

Furniture Design

Manufacture: A-Zenith

Dezeen Awards 2022

Gold Idea Design Award 2019

FLEX

Material Research

Furniture Design

Manufacture: A-Zenith

Dezeen Awards 2022

Gold Idea Design Award 2019

FLEX

Material Research

Furniture Design

Manufacture: A-Zenith

Dezeen Awards 2022

Gold Idea Design Award 2019